Working Performance of Roll Forming Machine

The rolling forming machine has the principle of the average force of each pass, which can prolong the service life of the roll. In production, it should be designed to be balanced in force, precise in processing, and convenient in installation and adjustment. The cold bending machine ensures the strength of the material, improves the quality of the supporting steel arch, greatly improves the work efficiency, and the operation is simple and clear. Compared with the two, both have good working performance.

Roll forming is a new process and new technology of sheet metal forming that is material-saving, energy-saving and efficient. Using this process, the roll forming machine can not only produce high-quality steel products, but also shorten the product development cycle, improve production efficiency, and improve the market competitiveness of the enterprise.

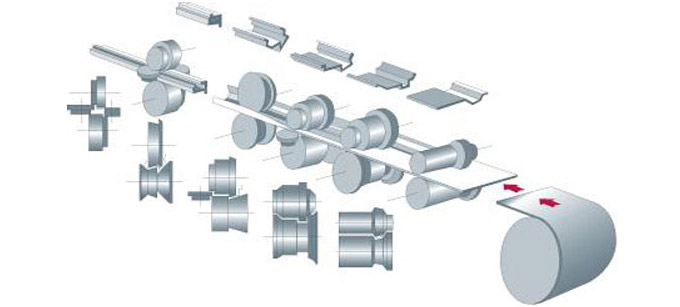

The general process of roll forming machine includes: single sheet forming, roll forming and continuous forming, combined forming.

1. The single sheet forming process is to cut the sheet into a specified length in advance, and then send the sheet into the roller forming machine through the material selection roller. After rolling, the profile can be directly collected and stored, which is especially suitable for products that are easily deformed after the sheet is formed. It is mostly used for small batch production. Its advantages are simple equipment, low investment and small floor space.

2. The process of roll forming and continuous forming is basically the same. The difference between them is: the joints of the continuously formed plates must be welded to make the plates continuously formed; the roll forming is a single roll supply. The investment and floor space of the roll forming machine required by these two processes are relatively large.

3. The combined forming process is a forming process for processing special steel. Shaped steel has special requirements for forming process and requires complicated roll forming machine equipment, which is suitable for the processing of high-strength plates. The equipment requirements are complex and the investment is high.

In recent years, cold-formed steel products as important structural parts have been widely used in many fields such as construction, automobile manufacturing, shipbuilding, electronics industry and machinery manufacturing. Its products range from ordinary guide rails, doors and windows and other structural parts to some special profiles manufactured for special purposes.