How to Distinguish the Quality of the Roll Forming Machine?

What determines the quality of a roll forming machine? When we order, how should we distinguish the quality? It is a very important link. When purchasing, if the control is not good, it will cause a lot of troubles in future production, or even be unusable at all. Not only will it cause capital loss, but more seriously, it will lead to abnormal production and the project will be forced to stop. , This loss is the heaviest. Therefore, we must strictly check when we purchase roll forming machine equipment. So, how should we distinguish the quality of the roll forming machine?

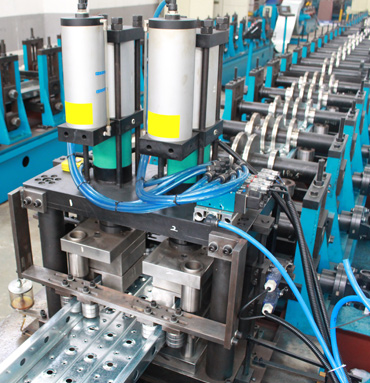

From a professional point of view, we first tell you that the quality of the roller forming machine is mainly related to the accuracy of the products, the quality of the rolls, the quality of the transmission mechanism, the circuit system, and the after-sales service. Next, we will elaborate on these points.

1. Product accuracy identification of roll forming machine

Product accuracy is the core of the entire equipment. If the product is unqualified and the accuracy is not enough, then this set of equipment is useless. Therefore, when purchasing equipment and testing machines, if the accuracy of the product does not meet the requirements of the drawings, it is necessary to find out whether the roll design is unreasonable or it has not been debugged.

Regardless of the reason why the accuracy is not up to the requirements, it must be debugged by the roller forming machine equipment manufacturer. If the roll is not well designed, it will be even more troublesome when it is brought to your own factory. Sometimes the master comes to install and debug, sometimes it is difficult to design well without modification, or it will be unstable in the future, easy to run out of materials, deformed, etc.

2. The roller quality identification of the roll forming machine

In addition to the accuracy to be achieved, the quality of the roll is also an important part. If the quality of the roll is not good, the accuracy of the products produced in the early stage can be reached, but when the equipment is used for a long time, if the quality of the roll is not good, it will be severely worn, causing the accuracy of the later product to not meet the standard. If the quality is not good, it will even break directly, or the shaft will break. In addition, by the way, what are the troubles caused by the poor quality of roll forming machines?

When the roll is broken, it needs to be reprocessed, and this process is very troublesome, and it has to go through many processes, such as initial turning, heat treatment, fine turning, plating and so on.

Of course, these can be handled by the original equipment manufacturer. However, when the equipment is used for a long time, it is difficult to deal with it when no manufacturer can help. At that time, it is necessary to find a designer to measure the rack size before redesigning the roll. Therefore, when purchasing the equipment, the roll drawing must be obtained from the manufacturer and save it.

And even if the manufacturer does it for you, you need to re-install and debug it yourself. This requires a very skilled master to complete, especially for profiles with complex cross-sections.

3. The quality identification of the transmission mechanism of the roll forming machine

A roll forming machine is most prone to wear. In addition to the rolls, there is also the wear of the transmission mechanism. Such as gears, chains, bearings, etc. Therefore, the bearings need to be installed with big brand bearings, and the gears need to be specially processed, because if these are damaged, they must be replaced in a complete set.

4. The identification of the circuit system of the roll forming machine

Regarding the circuit system, we also mentioned some of the most troublesome things. First of all, remind everyone that the circuit diagram of the device must be kept, so that when a fault occurs, the professional can solve it.

In particular, when the equipment uses the PLC, the PLC program must be backed up. When there is a problem with the PLC, it is much more convenient to buy the same model and re-import the program. However, when the program cannot be restored, it is a hassle. You need to hire a programmer to write the program on the spot and debug it on the spot. Therefore, we must pay attention to the quality of the circuit components when we purchase the equipment of the roll forming machine. We can use the electrical appliances of the big brands, and try to use the big brands as much as possible.

5. After-sales service of roll forming machine

No matter how good the quality of the product is, it should be supported by the manufacturer's perfect after-sales service, including door-to-door service, or technical consultation and cooperation through the Internet or telephone. Therefore, when we purchase, we should choose a manufacturer with a high reputation.

To identify the reputation of a manufacturer, we need to understand from many aspects, from the field to the strength, including the size of the plant, the number of personnel and so on, and to understand the negative impact on the Internet, to understand the successful cases, and so on.