Importance and Application of Straightening Mechanism in Rolling Forming Machine

Ⅰ. The importance of the straightening mechanism for the roll forming machine

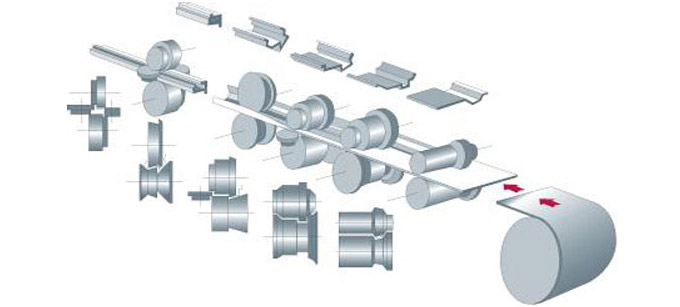

In the process of roll forming, due to the combination of the stress generated by bending and the residual stress of the strip, the formed profiles often appear side bending, warping, and twisting.

The best way to solve this problem is to install a straightening mechanism at the end of the roll forming machine, which can effectively solve various distortion problems. Therefore, the straightening mechanism is a very important part of the roll forming machine.

1. Common twisting methods:

Side bending: bending in the horizontal direction.

Warping: bending in the vertical direction.

Twist: Spiral twist.

2. The basic principle of straightening

In the case of side bending or warping, it is only necessary to apply pressure in the opposite direction through the straightening mechanism of the roll forming machine. When the strength of the straightening mechanism is adjusted to the appropriate level, it will produce permanent deformation, that is, the profile can be corrected. The straightening mechanism is generally installed between the last roll and the cutting device.

3. Common straightening mechanism

(1) Straightening roller

Straightening rollers are the simplest and most durable straightening tools, and are simple in design, easy to install and low cost. This kind of straightening device is very common in many roll forming machines, especially roll forming machines. The straightening method of two upper rolls and one roll is very common, and it is a very important straightening mechanism.

(2) Straightening die

Straightening die is also a commonly used straightening mechanism. It is designed to wrap around the profile section.

Ⅱ. Application method of straightening head in the process of rolling forming machine

The straightening head is often used in the roll forming process. When the formed product is bent, twisted, corrugated, etc., the straightening head can effectively correct these problems.

In some rolling forming machine manufacturing factories, in order to reduce production costs, or for some profiles with low requirements, this straightening head device may be omitted. For forming machines with relatively high requirements, we recommend installing the straightening head , which plays a very important role in the later profile correction.

1. Composition of straightening head

The straightening head is composed of a support frame and a straightening die. Different manufacturers of the straightening die of the roll forming machine have different methods. Generally, it consists of a die with a broken face, or consists of several groups of rollers. The ultimate purpose is to achieving the effect of exerting pressure on different faces.

2. Installation of straightening head

During the product forming process, internal stress is generated, so the straightening head should be installed at the end of the forming roll, before the cutting device.

For profiles with serious bending deformation, the straightening head of the roll forming machine cannot be corrected to the best effect. The straightening head is only suitable for the correction of slight bending deformation. Therefore, the most important thing is to adjust the forming of the main machine roll.