Different Components of Roll Forming Machine

Each metal roll forming machine has different parts, depending on the product being roll-formed, and may require more or fewer parts to handle different sizes, speeds, and complexities. However, some common parts of the forming machine are common to most machines, including:

1. Power supply of roll forming machine

An important part of a rolling mill is how it is powered and how it operates. Most on-site rolling mills use electricity as the primary power source, but there are also smaller portable rolling mills that are powered by gas.

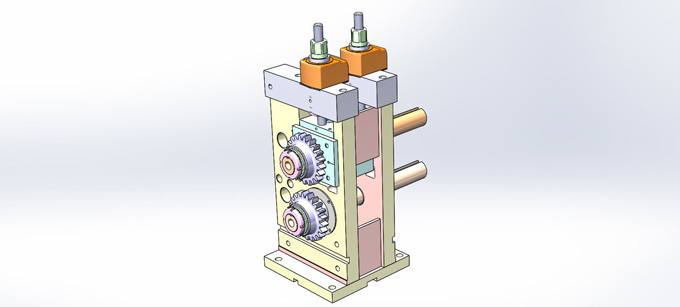

2. The forming roller of the roll forming machine

Forming rolls and forming stations are metal passing through a single part formed in a bent or desired shape. The forming rolls are assembled together in progressive series to complete the process used to form the final product. Most rollers are made of hard chrome steel or stainless steel. For some machines, the forming roll is also the drive roll.

3. The drive roller of the roll forming machine

Drive rollers are used to move the metal through the machine. Some rolling mills combine forming and driving rolls, while others separate the driving and forming functions. Separating the two reduces stress on the metal and reduces the chance of oil canning. Drive rollers are usually made of metal or polyurethane.

4. The forming station of the roll forming machine

A forming station is a location where metal is bent or manipulated by a pair of forming rolls. In fact, the more forming stations in the machine, the higher the quality of the finished product, since incremental forming reduces the stress on the material. For example, having more forming stations in a metal roofing roll forming machine helps to minimize the possibility of oil canning.

5. Shearing machine or guillotine of roll forming machine

If metal needs to be cut in any way, shape or form in a roll forming machine, it must have a shearing machine, sometimes called a guillotine, to cut the metal part or assembly to a specified length. Shears are common in metal coil and sheet processing rolling mills. In addition, rolling mills with shears are divided into two different cutting methods:

(1) Post-shear

Metal parts are first formed in a forming station and then cut. One of the benefits of post-shear is that there are no length restrictions. Products can be cut to a foot length or less without any issues.

(2) Pre-shear

The metal is cut before passing through the forming station at the entrance of the machine. In contrast to post-shear, pre-shear has a shorter length limit. However, pre-shear provides a cleaner cut for flat or unrolled metal.