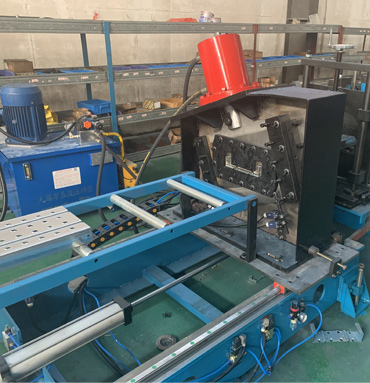

Restraining Dust roll forming machine from BOSJ in our company,The original production process is: strip cutting → blanking → deep drawing → punching. The long process flow and the large number of mold sets require a total of 3 sets of molds to complete the stamping of the product. The mold and production costs are high, the efficiency is low, and the equipment load in the stamping workshop is a major bottleneck that affects the production schedule. In order to solve this problem, combining the actual production and the design structure of the cold die, through the optimization analysis of the product drawings and technical requirements, the new process plan was determined as: strip cutting → blanking and deep drawing composite die punching, only A set of composite molds can complete the press forming of the product, and the processing is performed by a 100KN press, which improves the production efficiency by more than 5 times.

Restraining Dust roll forming machine Mold structure and working process

The structure of the blanking drawing and punching composite mold adopts a front-mounted composite mold: the blanking punch, punching punch, and drawing die are part of the upper die; the blanking punch, punching die, and drawing die are under Mold part.

When punching, the strip is fed into the mold, positioned by three blanking pins, and placed flat on the blanking die. The upper mold moves down with the equipment slider to press the strip to compact the strip. The slider continues to move down, the large convex die (blank die and deep drawing die) falls out of the round material, the slider continues to move down, the large convex die and small convex die (punching concave die and deep drawing die) contact , Deepen the round material dropped in the upper step, after the completion of the slider continues to move down, punch punch and small convex die contact, equipment slider to the bottom dead center to complete the punching step.

The slider moves up, the workpiece remains in the lower mold after forming, and the workpiece is held out by the support ring. If the workpiece remains in the upper mold, the discharge plate ejects the workpiece, and the upper mold returns to the top dead point with the slider. cycle. The workpiece is formed in a mold

The entire working cycle is simply summarized as: blanking → deep drawing → punching → unloading.