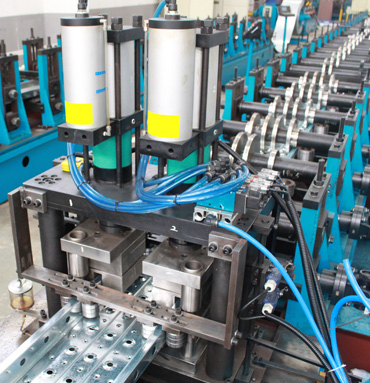

A metal arched Corrugated Sheet roll forming machine, which is characterized in that a motor and a hydraulic oil pump are provided at the front of the frame, and oil is supplied to the hydraulic motor of the straight plate forming part and the bent plate forming part; the straight plate forming part provided on the frame The front end is provided with a feed guide and 13 pairs of forming rolls, and a straight plate pressing angle and a straight plate cutter are provided at the rear; the bent plate forming part set on the frame is composed of a guide wheel, a side roll group, and a bottom roll group Composition; using sprocket and gear transmission. The advantage is that it is easy to carry and move, only 380V power supply is needed, and it can be installed on site for use. Suitable for forming long-span metal arch corrugated roof panels.

This fully automatic pressing equipment has a reasonable structure design, convenient operation and complete functions. All operations from feeding-drawing-feeding-pressing-cutting-all adopt automatic operation mode. And now the new technical concept makes this kind of color steel equipment also have the advantages of operation, maintenance, maintenance, mechanical debugging, easy mold replacement, etc.

When installing each steel plate of the color steel tile press equipment, the edges should be accurately placed on the previous steel plate and clamped with the previous steel plate until both ends of the steel plate are fixed. A simple and effective method is to clamp the overlapped steel plates with a pair of jaws. In South China, color panels are generally designed as single-layer color panels. In order to reduce solar radiation heat from entering the interior of the building, a thermal insulation layer can be installed in the roof system when installing roof panels. There is a very simple, economical and effective method, which is to install double-sided reflective foil film on the purlins or slats before installing the roofing steel plate. This method can also be used as steam insulation to reduce condensation.

Color steel tile compactor equipment forming consists of unwinding, forming, and post-forming cutting. The products produced are flat and beautiful in appearance, uniform in paint, high in strength, and durable. They are widely used in industrial civil buildings, such as factory buildings, warehouses, and machine garages. , Hangars, stadiums, exhibition halls, theaters and other rooms and walls. The center line of the upper and lower rolls of the tile pressing machine should be on the same plane line, which is based on the center wheel. The flatness is not greater than 1mm. The gap between the upper and lower rolls in each row is equal, and the gap deviation is + 0.1mm. Debug with a conventional measuring tool or feeler.

The product is used in the production of various industrial plants, warehouses and other roofs. It has the advantages of high wave crest and high strength. It is safe and reliable for overlap installation, and has strong waterproof and anti-riot performance. The profile plate produced by this machine solves the conventional series of profile plate. The problem of roof leakage, combined with an arching machine, can be used to make a beamless arched roof.