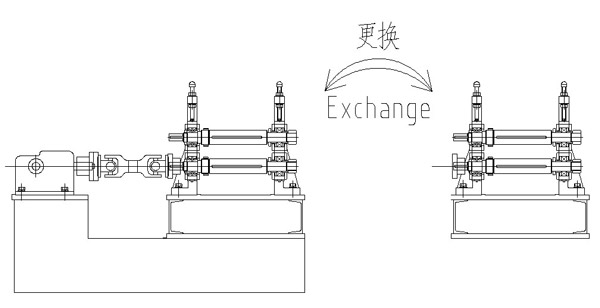

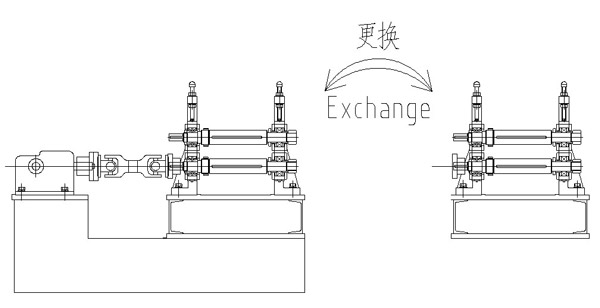

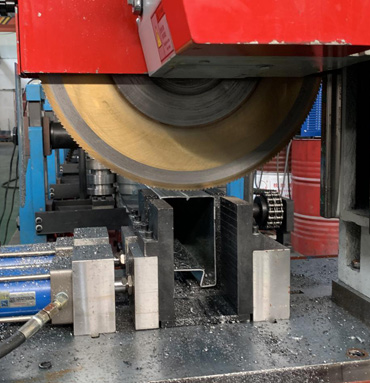

It is well known that in the cold-formed profiled pipe production line, since the profile of the profiled pipe is more complicated, the number of molding passes is larger, such as the common standard profile specified in the product standard. Cross-sections of rectangular tubes, square-shaped tubes, steel doors and windows frames used in the construction and automotive industries, P-tubes with complex shapes, and 8-shaped tubes. Cassette roll forming is the structure according to the frame of product features design for rapid replacing structure used for change roll forming products. Several forming frames to form a whole, quick-change cassettes, different production of cold-formed products just quick replacement cassettes cannot exceed 30 minutes by a roll forming product to another product, meet a variety of roll forming production requirements. You can remove the quick change cassette of the original product, then set up a quick change cassette for making a new product. It is versatile by using the same machine base and changing rollers to produce different products. The cassette rollformer has a base with fixed motorization, and the rollforming heads or stands installed on a removable base called cassette or raft.

The roll forming line, therefore, involves 2 or more series of cassettes with various rollforming stands, and by changing the cassettes, you change the type of profile, without the need of any particular adjustment to the line.

Depending on the model, there are various solutions to make the change of cassettes in the shortest possible time, including semi-automatic motorization release systems.

The number of rollforming stands for each cassette can be adapted to the capacity of the available overhead crane/forklift.

With rollforming lines that need to be equipped with many sets of rollers, the solution with rollforming cassettes makes off-line tools set up possible.

Depending on the requirements, we also provide the technologies upstream and downstream of the rollforming process, for example, decoiling and straightening, head/tail welding, coil perforation, in-line, welding, cut-to-Length, in-line calendering, stacking and packing systems.